Logic elements

Logic elements are multi-purpose devices used with other cartridge valves to create pressure-, flow-, and direction-control circuits. Flow ratings up to 400 l/min [100 US gal/min] and pressure ratings up to 350 bar [5,000 psi] are available for use in applications like fixed-displacement pump load sensing or bypass-type pressure-compensated flow control.

Features and benefits

- Logic elements are key to designing cost-effective circuits, limited only by the imagination of the designer.

- They can be used to perform many different functions, including pressure control, flow control, and compensation.

- Poppet-style options are available for high flow and low leakage performance.

- Pilot-to-close valves can efficiently bypass excess flow and improve system efficiency.

- Pressure compensators can be combined with needle valve or proportional valve to maintain constant flow, independent of load pressure.

- Our logic elements include hardened and ground spools, and/or honed sleeves, poppets, and sharp-edged ground steel seats, providing durability, dirt tolerance, reliable seating and fast cycling.

Applications

- Agriculture

- Construction

- Cranes and material handling

- Forestry

- Lawn and turf

- Road building

Logic element types

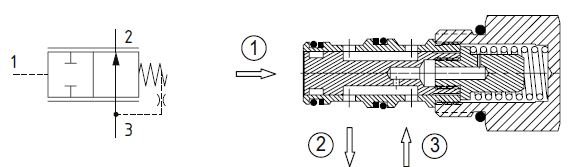

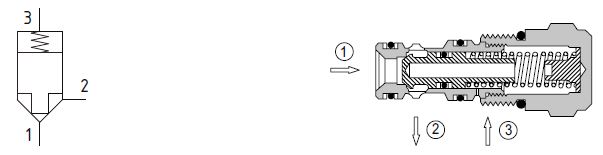

Restrictive pressure compensator

Restrictive pressure compensators are normally open, internally drained spool valves with a separate pilot port. By connecting the pilot port 1 upstream of the control orifice and the outlet of the orifice to port 3, the valve senses the pressure difference. The spool moves and restricts the outlet flow to maintain a constant pressure differential and flow across the control orifice.

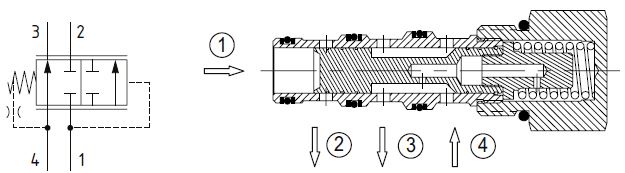

Priority pressure compensator

Priority pressure compensators are normally open between port 4 and port 3, with ports 1 and 2 blocked. When the pressure differential across the orifice exceeds the spring setting, priority flow is controlled by the restriction created between port 4 and port 3 and the excess flow passes to port 2. These valves maintain a constant priority flow, while diverting the excess flow to a secondary system.

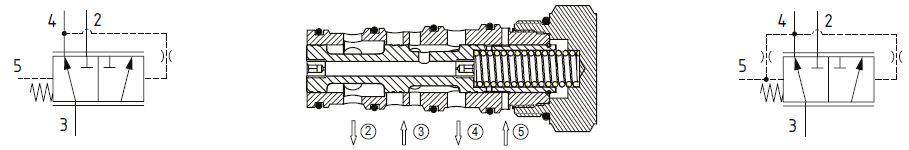

Load sense priority pressure compensator

Load sense priority pressure compensators provide a priority flow to a circuit, such as steering, based on the load sense pressure from an actuator at port 5. With the inlet at port 3, priority flow is controlled at port 4 based on the difference between the load sense pressure and the pressure of the controlled flow. Excess flow passes to another part of the circuit at port 2.

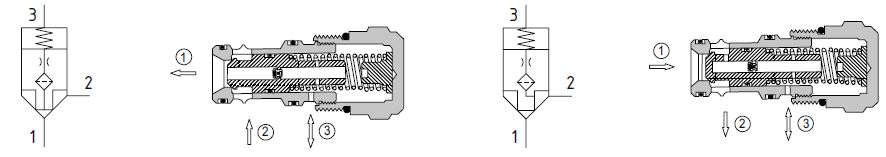

Vent to open poppet type logic element

These are normally closed, vent to open, poppet type valves with an internal orifice connecting either port 1 (DPS **B) or port 2 (DPS **S) to the spring chamber and port 3. Both valve types can be used in conjunction with pilot valves to create directional controls.

Pilot to close poppet type logic element

These are normally closed, pilot to close, poppet type valves that allow free flow in both directions from port 1 to port 2 and port 2 to port 1 if the pressure at port 3 is minimal. Pressure in port 3 will act over the full area of the poppet, piloting it closed. This valve can be used in directional valve functions using pilot pressure to close the valve and venting the spring chamber to open it.

Double blocking poppet type logic element

These are normally closed, vent to open, poppet valves that block flow from both 1 to 2 and 2 to 1 when the drain port 3 is blocked. An orifice in the spool connects port 1 to port 3, which allows remote control of the pressure in the spring chamber and therefore the pressure required at port 1 to open the valve. This valve uniquely provides poppet type piloted pressure control function for high flow rates.

Pilot to close spool type logic element

These are normally closed, spool type valves that are biased-closed by a spring. When pressure in port 1 reaches the spring set pressure, the spool will open port 1 to port 2. Pressure at the pilot port 3 adds to the opening pressure of the valve. These valves are one of the most versatile logic element designs and can be used in directional, pressure control, and flow control circuits.

Vent to open spool type logic element

These are normally closed, spool type valves that are biased-closed by a spring. An orifice through the spool connects port 1 to port 3, which allows remote control of the valve by connecting port 3 to a pressure control or a solenoid valve. These valves can be used as unloading valves or in pressure control and bypass circuits.

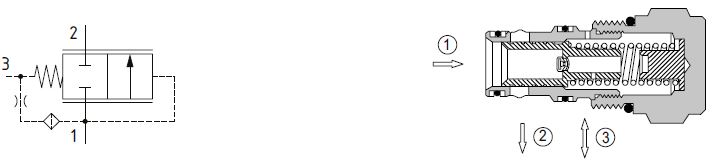

Pilot to open spool type logic element

These are normally open, spool type valves that are biased-open by a spring. Port 1 is open to port 2 until the pressure in port 1 is enough to overcome the spring force offset pressure and plus the pressure in the pilot port 3. They can be used as restrictive type pressure compensators or as a remotely operated pressure reducing valve.