Sequence and unloading valves

To control function timing and improve efficiency, sequence valves usually use a pressure signal to shift a spool, thereby opening or closing a flow path at a preset pressure. Our product range includes direct-acting, pilot-operated, kick-down, and unloading valves with flow ratings up to 250 l/min [60 US gal/min] and pressure ratings up to 350 bar [5,000 psi].

Features and benefits

- Direct acting sequence valves are ideal for constant flow and lower pressures.

- Pilot-operated sequence valves are well suited for varying flow and higher pressures.

- Unloading valves are helpful in reducing heat and increasing system efficiencies when applied at a pump outlet.

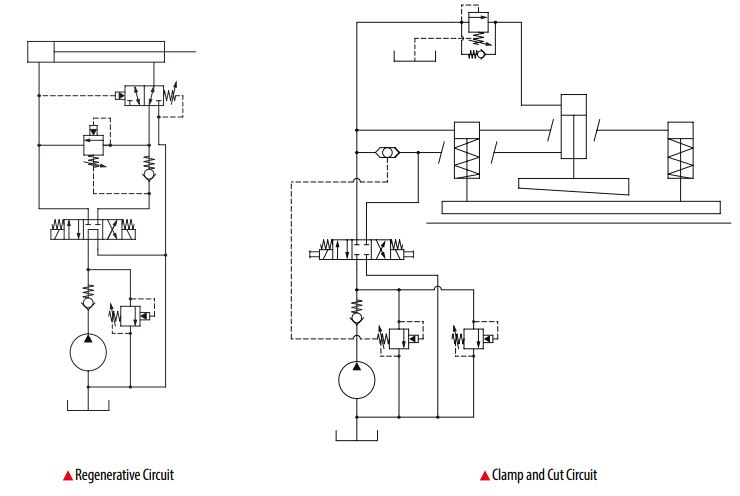

- Sequence valves are commonly used in accumulator charging systems, pump unloading in dual pump high-low circuits and sequencing operations such as clamp and lift applications.

Applications

- Agriculture

- Construction

- Forestry

- Lawn and turf

- Road building

Basic operation: Sequence valves

Sequence valves come in two forms: Hydraulically piloted spool valves and pressure sequence valves. Hydraulically piloted spool valves will open or close based on a pressure applied to a pilot port. Pressure sequence valves allow flow through the valve when the inlet pressure rises above the setting, allowing flow to a secondary function which can be used at pressure. These are available as direct acting and pilot operated valves. Sequence valves are similar in design to relief valves, with the difference being the addition of a spring chamber drain port. Sequence valves can be used to sequence a secondary operation within a system, as pressure compensators, or as load sense bypass valves.

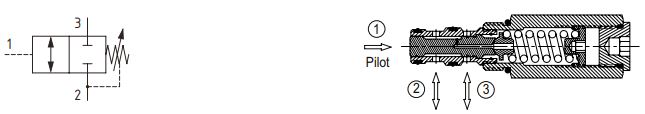

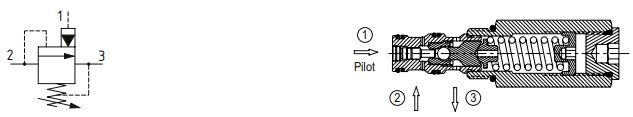

Hydraulically pilot operated spool type

The normally closed, pilot operated, spool type sequence valve opens port 2 to 3 when a set pilot pressure is reached. The normally open valve will close port 2 to 3 when the set pilot pressure is reached. These valves can be used to sequence a function in a separate part of the circuit by taking pilot pressure from another function.

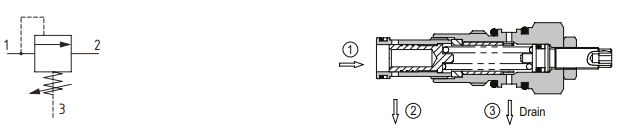

Direct-acting pressure sequence type

The direct acting pressure sequence valve is a normally closed, spool type controlling flow from the inlet port 1 to the sequenced port 2. When the pressure rises above the setting, the valve opens allowing flow port 1 to 2. With port 3 connected directly to tank, the valve will stay open if the pressure in port 1 is higher than the valve setting. The valve can be used in standard sequencing circuits, as a load sense compensator, or in regenerative systems where flow passes from port 2.

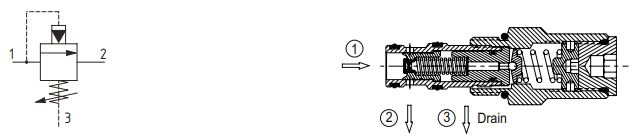

Pilot-operated pressure sequence type

The pilot operated sequence valve blocks flow from port 1 to 2, until pressure is sufficient to move the pilot poppet off its seat and overcome the opposing spring force. This creates a pressure differential across the spool, causing the spool to move back against a light spring. With port 3 connected directly to tank, the valve will remain open as long as the inlet pressure is higher than the setting. This design is ideal for sequencing cylinders or motors in clamp and cut or lift and tip circuits.

Pilot-operated kick down pressure sequence valve

The pilot operated kick down sequence valve blocks flow from port 1 to 2 until pressure is sufficient to move the pilot poppet off its seat and overcome the opposing spring force. This creates a pressure differential across the spool, causing the spool to move back against a light spring. This automatically opens the main spool spring chamber to port 2 allowing the inlet pressure to decrease to the pressure in port 2.

Basic operation: Unloading valves

Unloading valves are used to unload pump flow when an accumulator circuit is fully charged. The excess flow can pass directly to tank at minimum pressure drop or be used for a secondary circuit. The low flow pilot valve can be used in load sense systems or in combination with a logic element. The larger valves include the logic element and full flow relief function in a single cartridge. When the pressure in the pilot port falls, the valve will close, allowing the re-charging of the accumulator circuit.

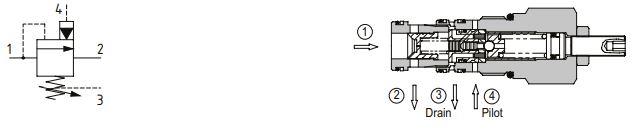

Low-flow pilot-unloading valve

The low flow pilot unloading valve is designed to be used in conjunction with a larger element or in a load sensing system. The valve blocks the flow from port 2 to port 3, until the pressure at port 1 is enough to pilot the ball off its seat. The area of the pilot piston is larger than the seat area, so when the pressure decays in the pilot line, the valve will close (re-seat) at a percentage lower than the setting, allowing pressure to rise again in port 2.

Unloading valve & priority unloading valve

With the standard unloading valve, inlet pressure is seen on the nose of the valve and system pressure (downstream of the system check valve) operates on the system pilot port. When inlet pressure rises to the valve setting, the relief section opens and the system pressure at the pilot port acts on the pilot piston to hold the valve in the open position. The priority unloading valve has a separate spring chamber drain that allows the flow downstream to be used at a pressure without affecting the setting of the valve.

Typical application diagrams