Check valves

We offer a broad portfolio of check valves with flow ratings up to 300 l/min [80 US gal/min] and pressure ratings up to 350 bar [5,000 psi]. Integrated circuit solution (ICS) check valves are available in standard, reverse-flow, slip-in, and inline models, and our screw-in cartridge valves are operated directly or by pilot. Our direct-operated valves fit into industry-standard cavities and may be installed in manifolds, and our pilot-operated models are often used for position-load locking or, when neither overrunning loads nor release speed are factors, as alternatives to counterbalance valves.

Features and benefits

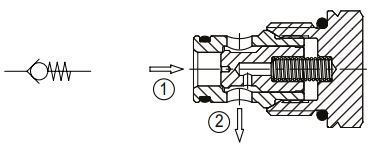

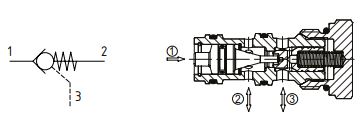

- Standard check valves are suitable for most applications; these valves have fully guided poppets that always block flow from 2 to 1 (see Basic operation section below).

- Integral orifices are available in some models for free flow in one direction and controlled speed in the opposite direction.

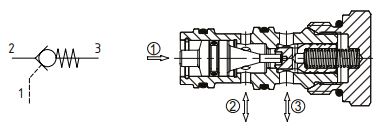

- Reverse flow options available where housing or size constraints require an opposite flow path. These valves have guided poppets that block flow from 1 to 2 and are spring biased closed until sufficient pressure is applied at 2 to open flow to 1.

- Slip-in check valves utilize small cavities retained by SAE plugs or other cartridge valves. Slip-in check valves are ideal for use in manifolds where space saving is critical.

- In-line check versions available for simplifying machine plumbing. These valves can be used as safety bypasses for flow surges through filters and heat exchangers. Higher spring rates can be utilized to generate pilot pressure.

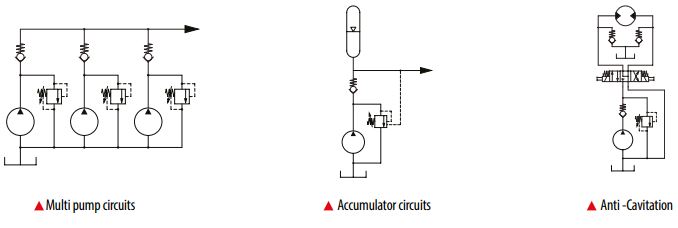

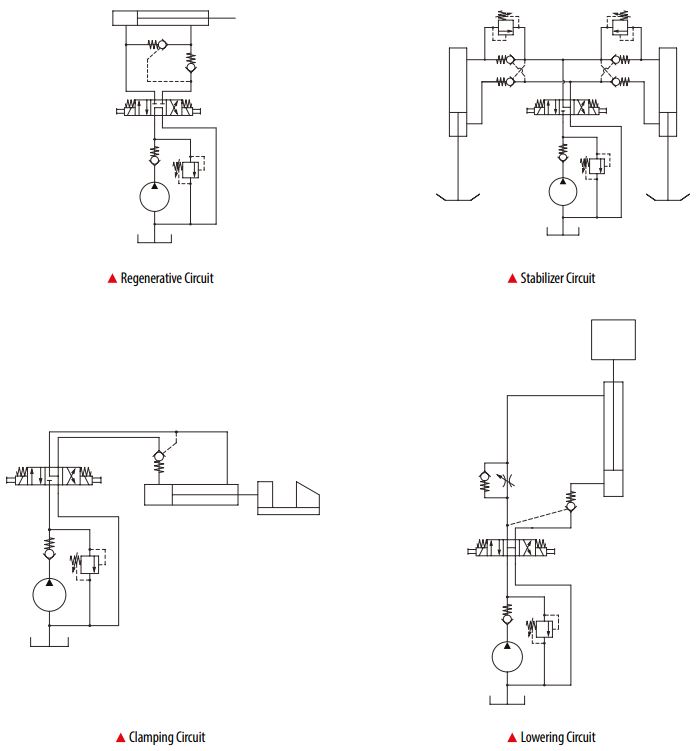

Applications

- Agriculture

- Construction

- Cranes and material handling

- Forestry

- Lawn and turf

- Road building

Basic operation

Check valves

Check valves allow free flow in one direction and prevent flow in the other. The valve can be of poppet or ball design with various cracking pressures.

Pilot-operated or pilot-to-open check valves can be opened by applying pressure to a pilot port acting on a larger area than the main seat of the valve. The ratio of the two areas is called the pilot ratio. These valves will hold a cylinder in position with minimal leakage.

Pilot-to-close check valves

Pilot-to-close check valves allow free flow through the valve until pressure is applied to the pilot port. They can be used in regenerative circuits or as circuit selection devices. Generally, the pilot ratio will be around 2:1, allowing the valve to close off when the pilot pressure is half of the load pressure.

Application notes

Check valves are used in a variety of applications where oil is required to travel in one direction only. In the other direction the oil cannot pass, and the valve will hold pressure based on minimal leakage past the poppet. The various cracking pressures allow the valves to be used as back pressure devices or in anti-cavitation circuits where minimal cracking pressure is required.