Shuttle valves

Danfoss offers primarily hot-oil shuttle valves and load shuttle valves with the latter configurable in either a normal or in-line direction. Available in many sizes with flow ratings up to 90 l/min [24 US gal/min] and pressure ratings up to 450 bar [6,500 psi], these valves can be used in a variety of ways for anything from load sensing to loop flushing.

Features and benefits

- Cartridge-style designs offer low pressure drop, reducing heat generation and improving efficiency.

- In-line designs can be installed directly to hoses without requiring a manifold, simplifying machine plumbing.

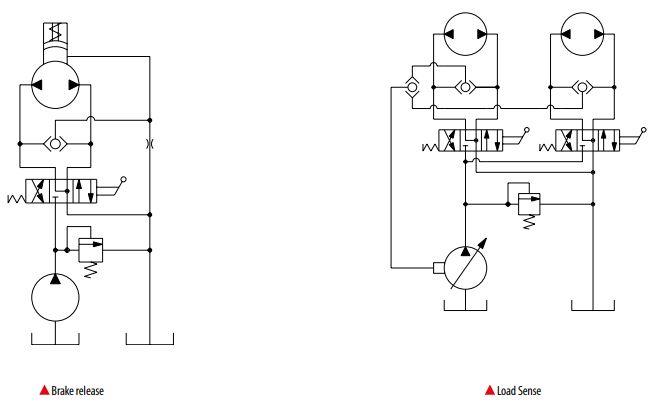

- Load shuttle valves have several common applications, including logic for load-sensing circuits and bi-directional motor brake release valve.

- Hot-oil shuttle valves are commonly used to divert fluid from the low-pressure side of a closed-circuit hydrostatic loop for cooling and/or filtering.

Applications

- Agriculture

- Construction

- Cranes and material handling

- Forestry

- Lawn and turf

- Road building

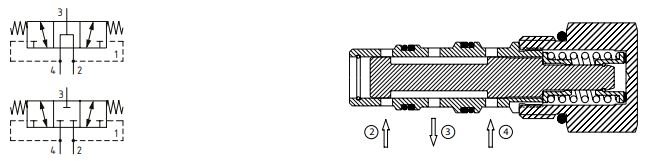

Basic operation: Load shuttle valves

Load shuttle valves sense the higher pressure between two lines and allow a signal to the third port, while blocking the lower pressure port. The valve will sense the pressure difference between port 1 and 3 with the higher pressure referenced to port 2.

Basic operation: Hot-oil shuttle valves

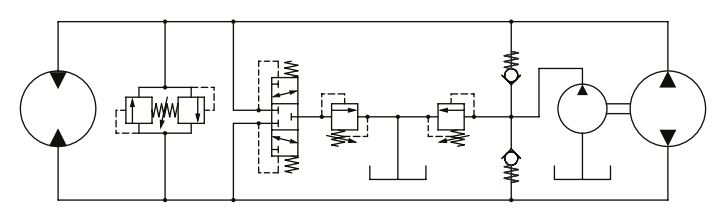

Hot-oil shuttle valves are spool type valves that are internally piloted, sensing two pressures and opening the lower pressure port to the outlet while blocking the higher-pressure port. The name is derived from its position in closed loop hydrostatic circuits where the hot oil from the motor outlet is diverted through a cooler. The exhaust flow can be regulated by balancing a purge relief valve setting, normally fitted to port 3 with the charge pump relief pressure.

Closed loop Hydrostatic transmission flushing circuit