Check valves

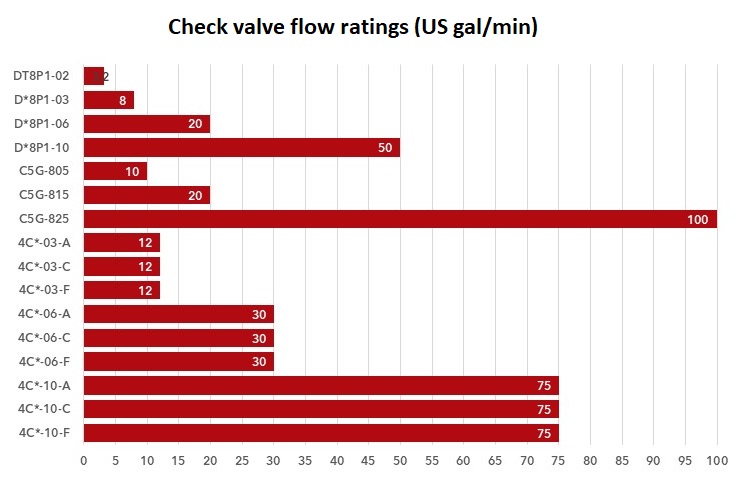

Our rugged Vickers by Danfoss check valves reliably handle flows up to 400 l/min [100 US gal/min] and pressures as high as 350 bar [5,000 psi]. Inline, right-angle, manifold-mounted, and pilot-operated models are available in a variety of styles, ensuring that you can find the perfect fit for your application.

Features and benefits

|

Valve Type |

Description |

|

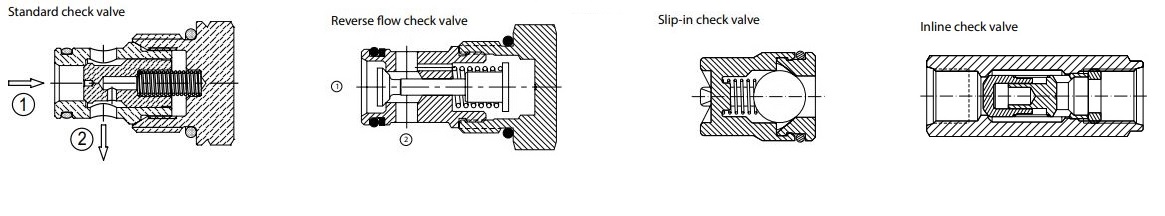

Standard Check Valves |

Suitable for most applications, these valves have fully guided poppets which always block flow from 2 to 1. They are spring biased closed until sufficient pressure is applied at 1 to open flow to 2. This pressure is commonly called the crack pressure. Several crack pressures are available for each model. This valve is also available with an integral orifice for free flow in one direction and controlled flow (speed) in the opposite direction. |

|

Reverse Flow Check Valves |

Useful for higher pressure applications or where housing or size constraints require this flow path, these valves have guided poppets that block flow from 1 to 2 and are spring biased closed until sufficient pressure is applied at 2 to open flow to 1. |

|

Slip-in Check Valves |

These valves are cartridges that drop into small cavities and are retained by SAE plugs or by other cartridge valves. They are ideal for use in manifolds where space savings is critical. Versions of these valves with Delrin® seats are also available for applications requiring extremely low leakage. |

|

Inline Check Valves |

Useful for simplifying machine plumbing, these valves can be used as safety bypasses for flow surges through filters and heat exchangers. With a higher spring rating, they can also be used as a means of generating pilot pressure.

|

Applications

- Die casting and foundry

- Machine tooling

- Marine and offshore

- Presses

- Primary metals

- Plastics

- Test equipment and simulation

Specifications

- Size: D02 to D10

- Pressure: Up to 350 bar [5,000 psi]

- Flow: Up to 400 l/min [100 US gal/min]

For more information, see Check Valves Catalog.