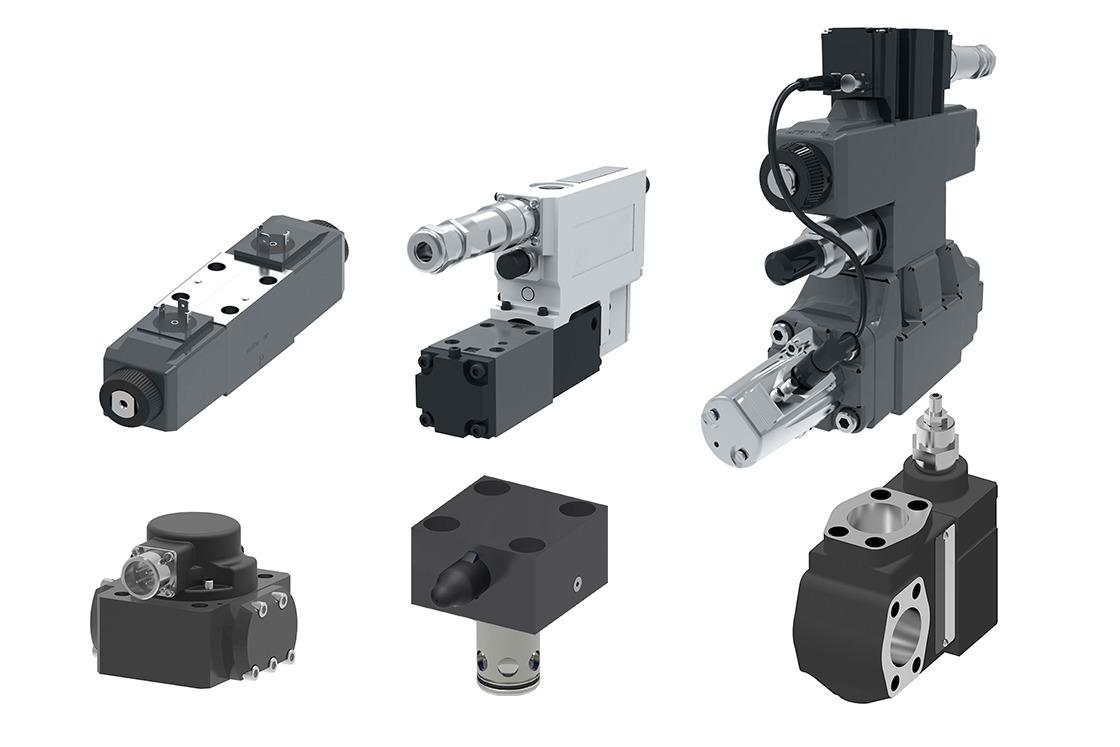

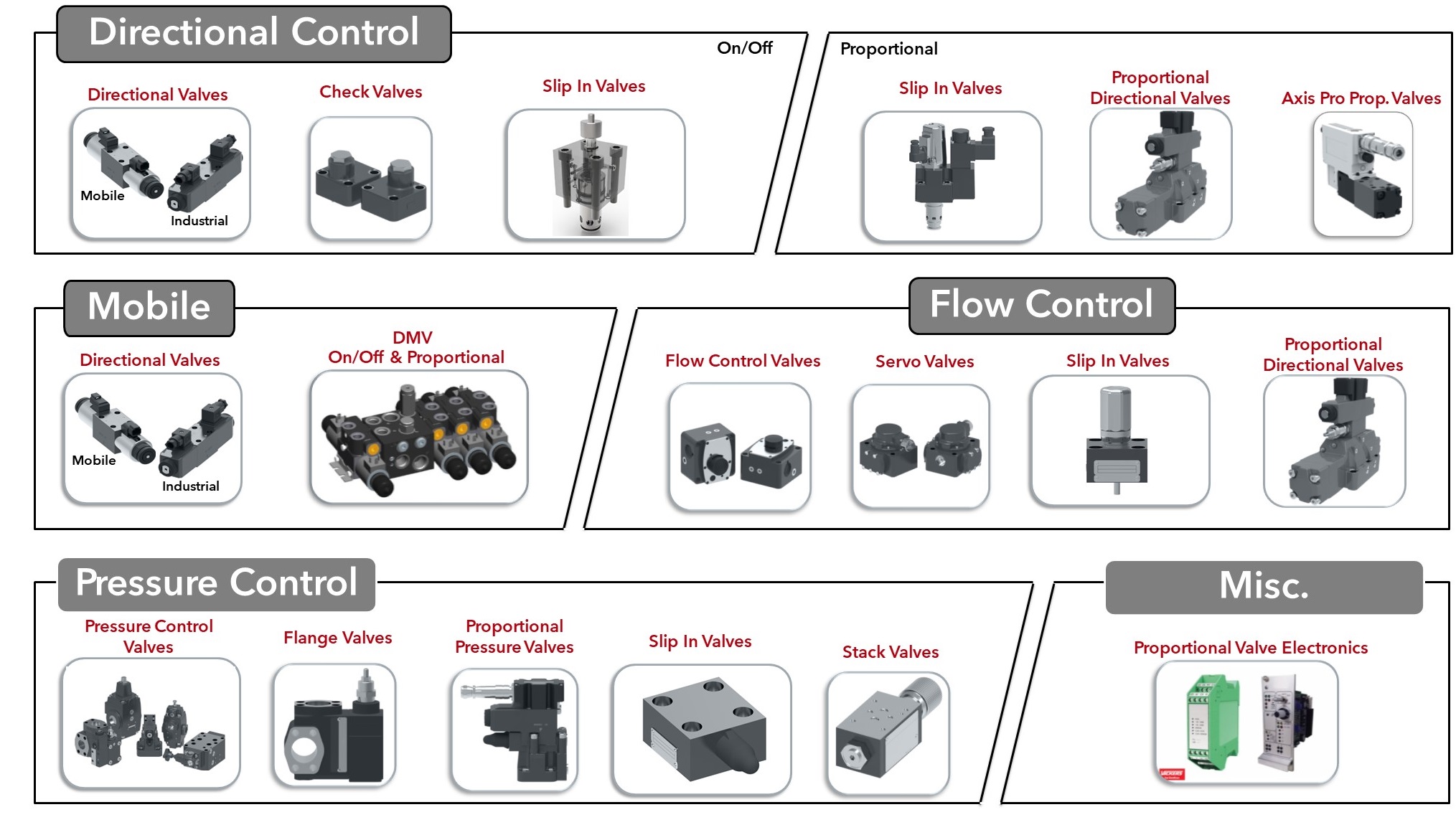

Industrial valves

With durable, time-tested industrial valves from the expansive Vickers by Danfoss line, you get reliable and accurate performance for complete control of even the most challenging applications.

Our industrial valves provide a variety of capabilities for directional, flow, and pressure control. Some valves offer multiple control capabilities. We also offer a wide variety of proportional valve electronics that enable you to build reliable solutions for various valve functions.

Products shown: 12

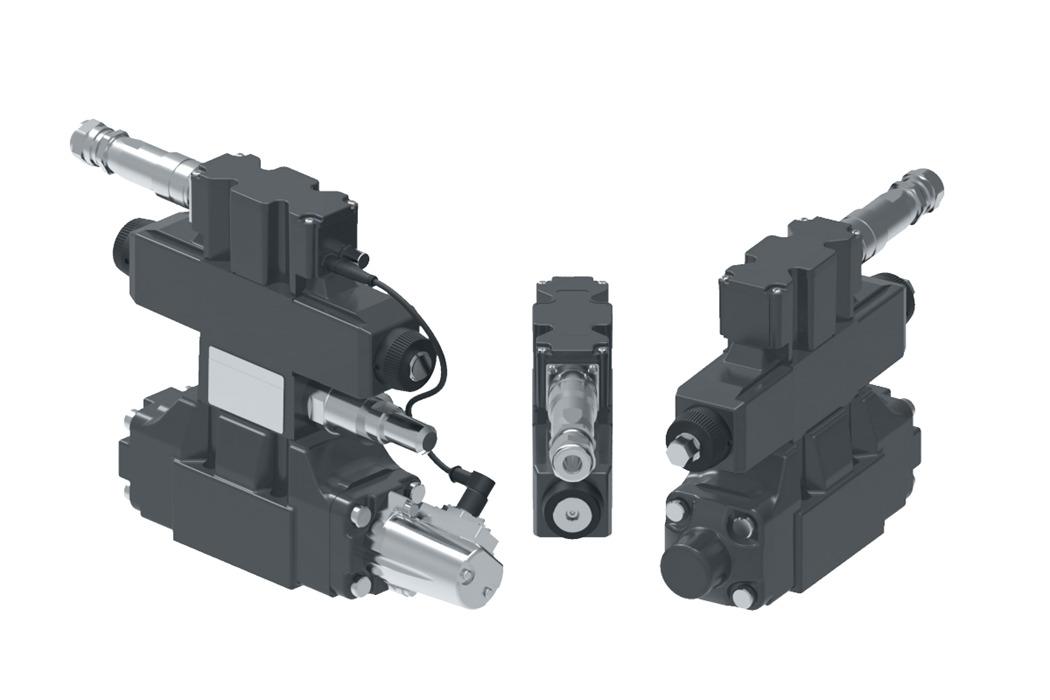

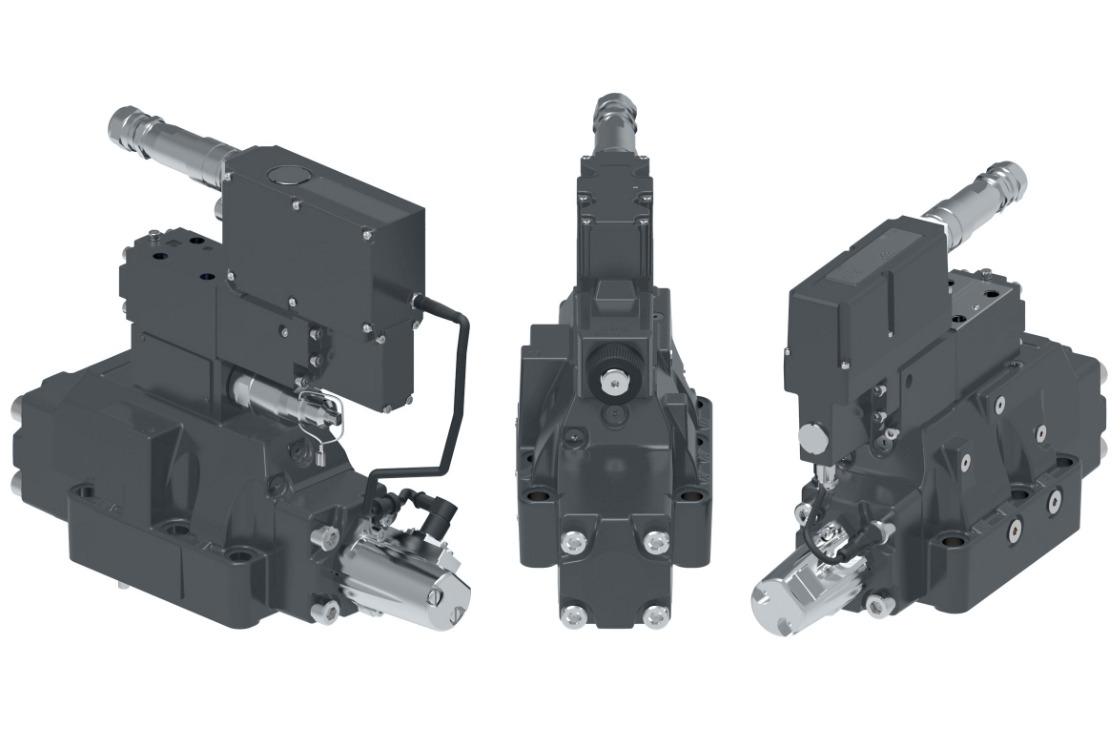

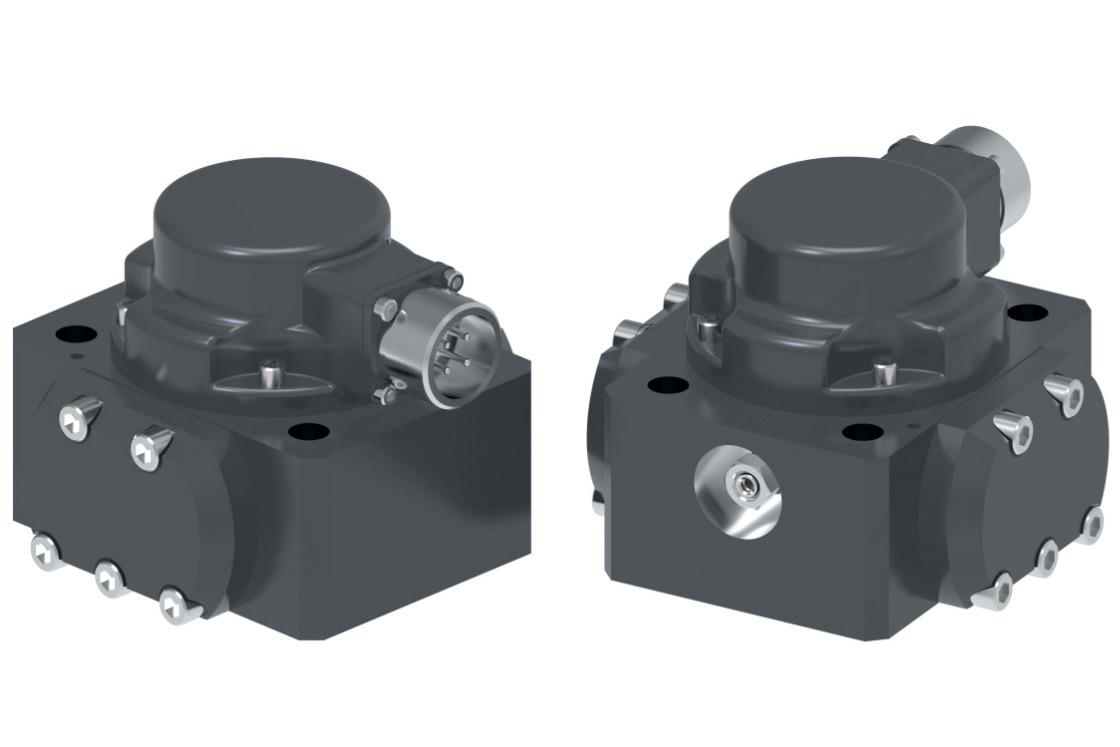

AxisPro proportional valves

AxisPro proportional valves' innovative designs offer intelligent, precise control and onboard diagnostics. With built-in support for popular communication protocols, these valves are easy to configure and maintain, giving you the flexibility to create custom solutions and make real-time changes. They provide long-lasting performance at pressures up to 350 bar [5,000 psi] and flows up to 375 l/min [99 US gal/min].

Proportional pressure valves

Vickers by Danfoss three-way pressure-reducing/relieving valves set output pressure as a function of electric current, regardless of system pressure or flow. For pressures up to 350 bar [5,000 psi] and flows up to 400 l/min [106 US gal/min], these valves are often used for the position control of a single-acting cylinder, height control of a combine header, pressure control of a clutch or brake, or pilot signaling of a directional control valve.

Directional control on/off valves

Vickers by Danfoss directional control (DG) valves can be actuated mechanically, by lever, or by solenoid, hydraulic, or pneumatic pilot. They feature three- or four-way directional control and are easily mountable on industry-standard surfaces. These time-tested valves can reliably handle flows up to 1,100 l/min [290 US gal/min] and pressures as high as 350 bar [5,000 psi].

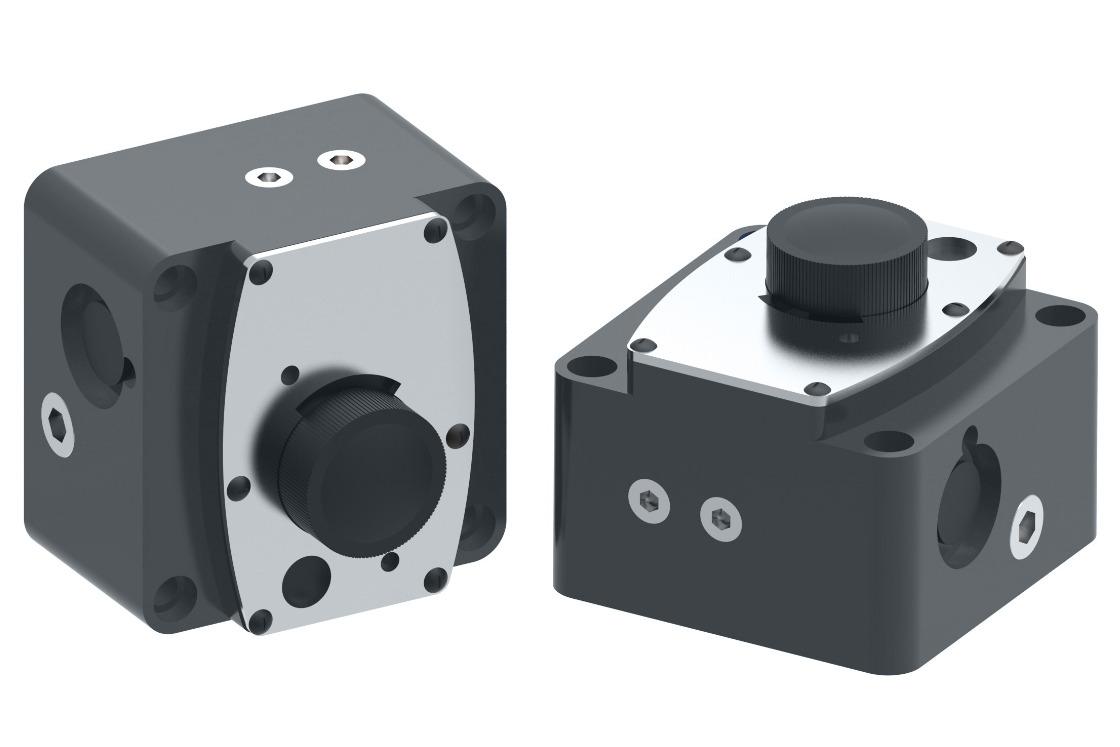

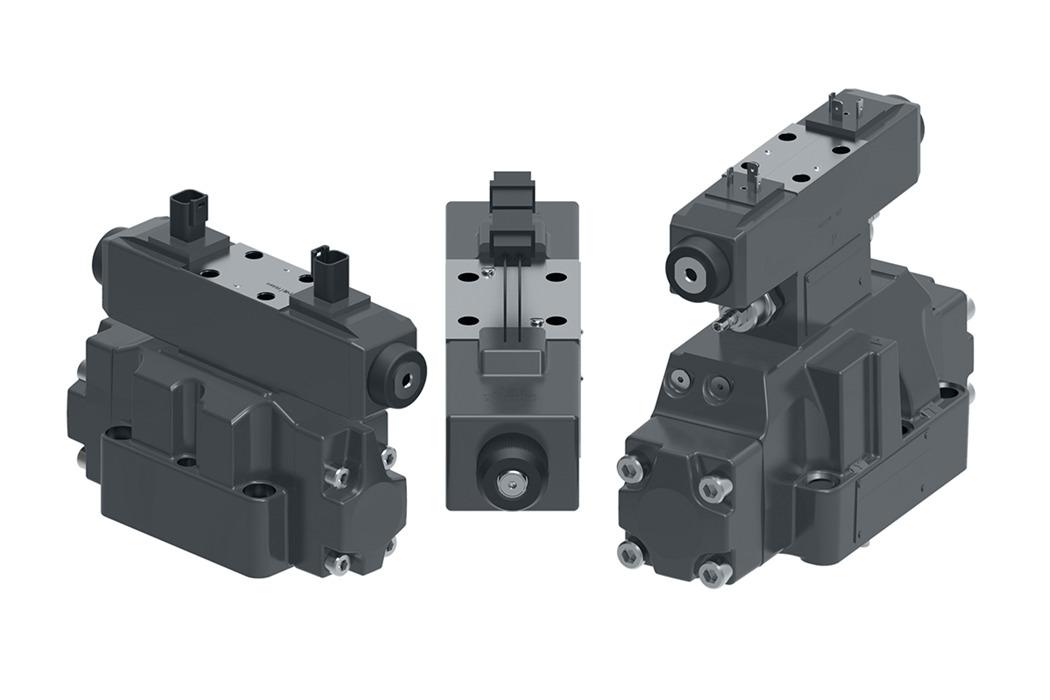

SystemStak modular valves

SystemStak is an innovative, compact system for sandwich-mounting modular valves between a directional control valve and a standard mounting surface. In addition to saving space, reducing installation costs, and increasing hydraulic system efficiency, SystemStak accommodates a full range of operating conditions at pressures up to 315 bar [4,500 psi] and flows up to 340 l/min [90 US gal/min].

Slip-in cartridge valves

For pressures up to 420 bar [5,000 psi] and flows up to 5,000 l/min [1,320 US gal/min], Vickers by Danfoss slip-in cartridge valves are ideal for high-flow systems. They are designed to reduce internal leakage and entirely prevent external leaks, providing better load-holding control, less pressure drop, faster response, and greater machine efficiency.

Servo valves

For consistent machine operation, Vickers by Danfoss servo valves provide closed-loop control with exact positioning, repeatable velocity profiles, and predictable force or torque regulation. At pressures up to 350 bar [5,000 psi] and flows up to 151 l/min [40 US gal/min], the symmetric designs enable dependable control-flow metering, minimal null shift, and frequency response over 100 Hz with a 90-degree phase lag.

Check valves

Our rugged Vickers by Danfoss check valves reliably handle flows up to 400 l/min [100 US gal/min] and pressures as high as 350 bar [5,000 psi]. Inline, right-angle, manifold-mounted, and pilot-operated models are available in a variety of styles, ensuring that you can find the perfect fit for your application.

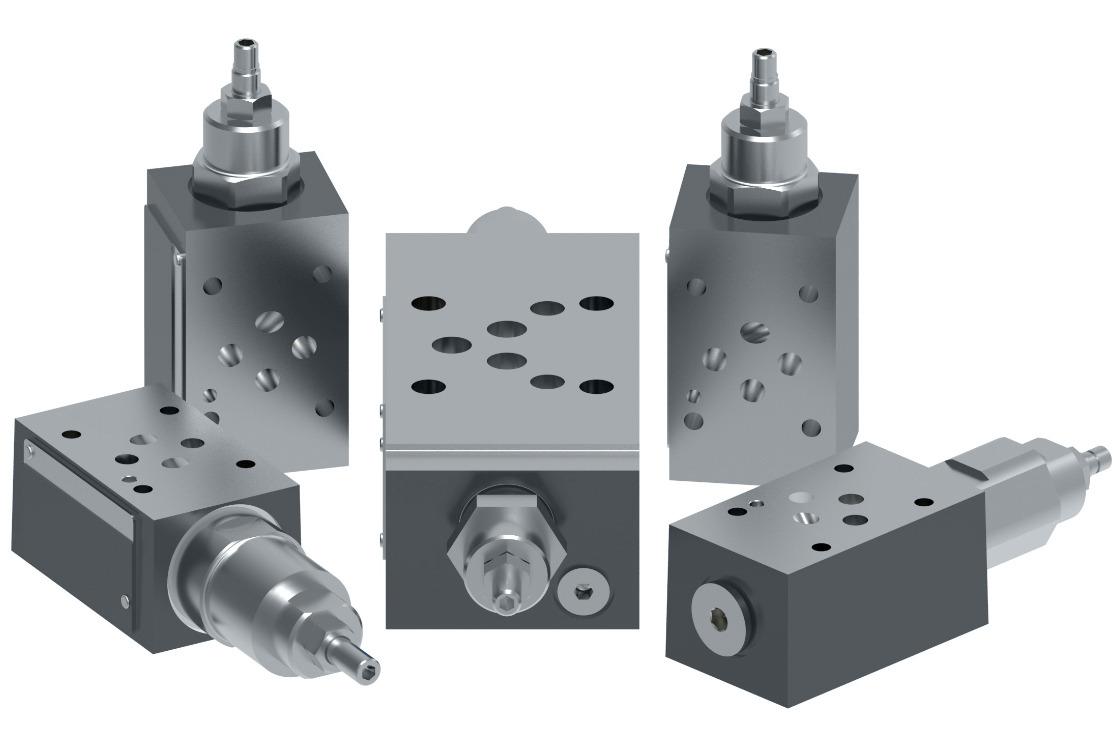

Pressure control valves

Vickers by Danfoss pressure control valves provide hydraulic system solutions for a variety of applications. With pressures up to 350 bar [5,000 psi] and flows up to 400 l/min [106 US gal/min], these valves include onboard ramp adjustment, superior moisture resistance, and valve enablement for easier interlock control.

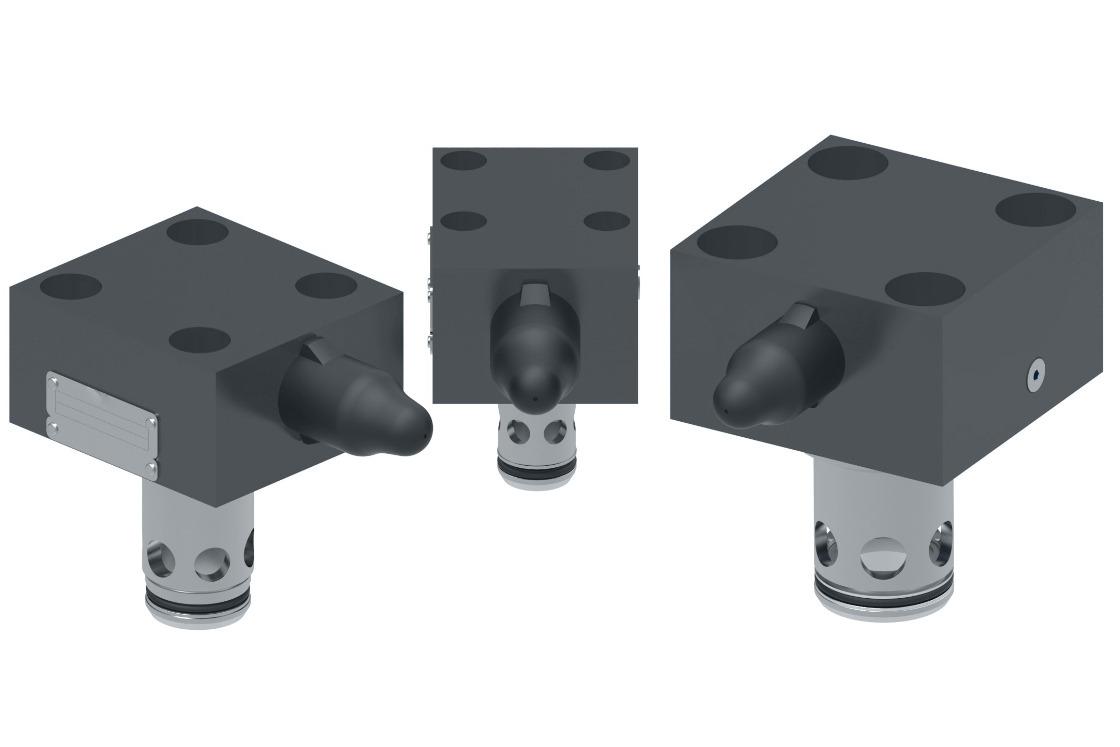

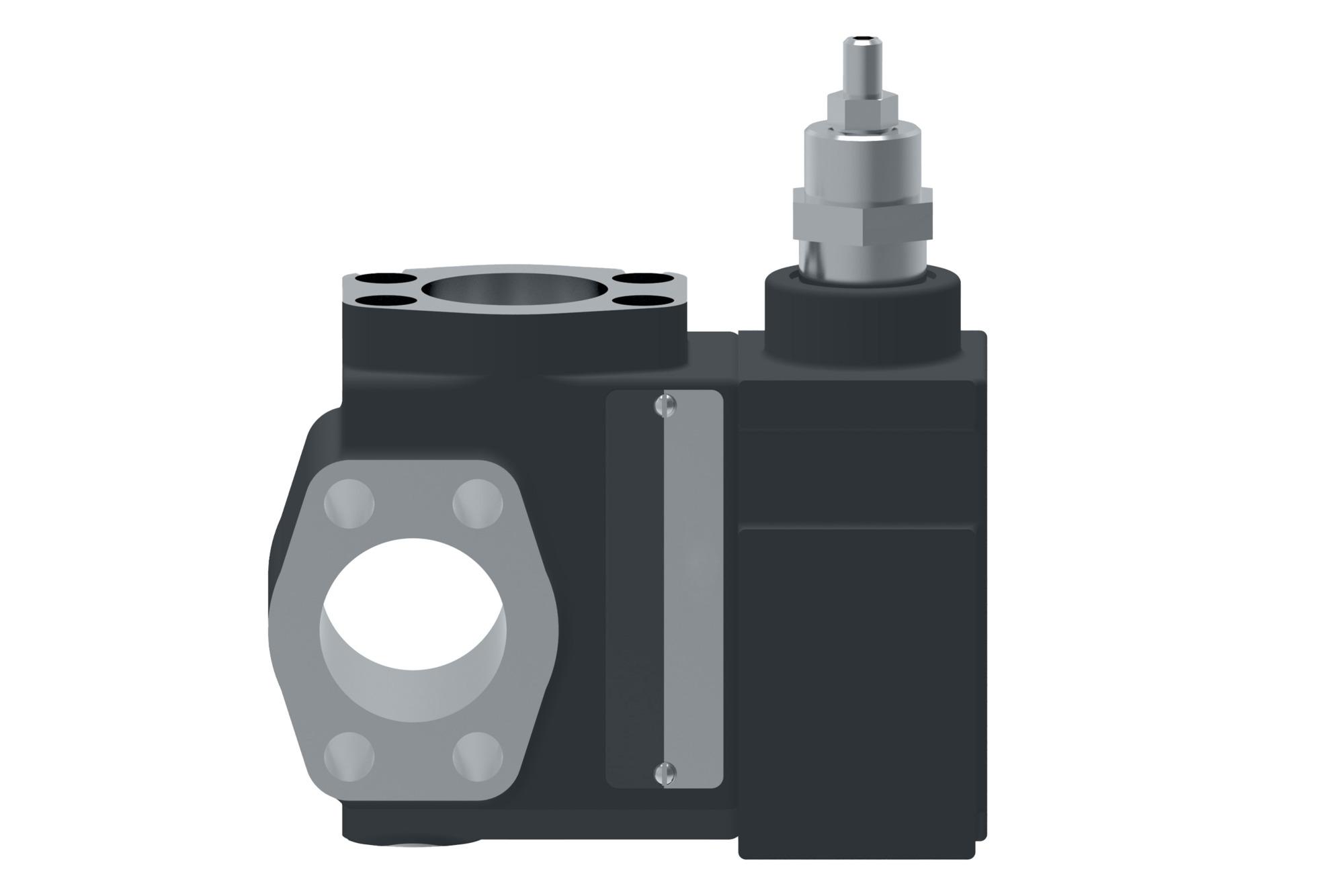

Flange valves

Vickers by Danfoss flange valves are mounted directly on pump flanges to minimize the potential for leakage. In addition to reducing installation costs and space requirements, the cartridge design of these valves ensures stable performance and fast opening and closing. Our unloading, check, and relief valves are suitable for pressures up to 350 bar [5,000 psi] and flows up to 750 l/min.